Proven performance

ColdBit is easier and quicker to lay than hot mix materials and can be laid by paver or by hand. The bitumen will not stick to tools or any surface used for storage.

ColdBit can be returned to storage if not used on-site and then can be used at a later date. Since there is no heat involved in laying ColdBit, the risk of burns and fume inhalation is eliminated.

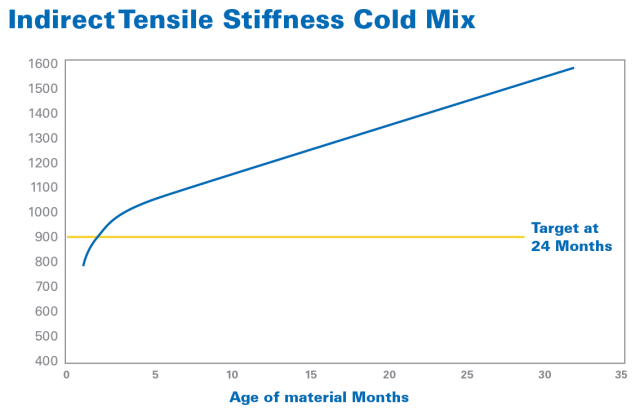

Performance statistics

ColdBit does not have heat retention problems commonly associated with hot mixed materials, so small economical quantities can be taken to the site.

This asphalt should be kept covered in depot storage. This prevents atmospheric deterioration and allows the material to last for several weeks.

Reduced environmental impact

ColdBit is a recycled product that complies with the UN’s Agenda 21.

Using recycled asphalt preserves the environment by conserving energy and reducing transportation. Hot plant emissions are avoided altogether along with the need to quarry and landfill.

A recycled base course for all projects.

Benefits of ColdBit include:

- Installation in all weather conditions and is instantly trafficable

- Can be overlaid with hot/cold material after a few hours

- Suitable for footpaths, planned and reactive pothole repairs

Unlike hot mix base course materials, ColdBit does not become unusable when cold, therefore all the material is utilized with no waste generated.

A flexible repair solution for all conditions.

In a recent case study, a section of canal path in Rotherham was repaired using 20mm ColdBit.

The typical spread rate of ColdBit is 10m2/T when laid 50mm thick which is approximately 15% more than most limestone alternatives.

Unlike hot mix base course materials, ColdBit does not become unusable when cold, therefore all the material is utilized.